The CPSC has recently announced the recall of over one million Anker 321 Power Banks (model A1288)[1]. This recall is due to defects in the lithium-ion battery cells, which may overheat and pose serious fire and burn hazards.

Ultimately, this issue stems from preventable negligence in the supply chain quality control and supplier audit, highlighting the critical necessity of implementing robust regulatory compliance solutions.

As a responsible leading adapter supplier, we regard safety as an absolute non-negotiable red line. To uphold this commitment and deliver a reliable power supply, UE Electronic has established and strictly implemented a rigorous multi-tiered supplier management system designed to prevent such risks at the source.

Copyright photo from: https://www.freepik.com/free-photo/close-up-engineer-using-tablet-design-solar-panels-factory-layouts_418373810.htm#from_element=cross_selling__photo

Strict Supplier Qualification Process

To guarantee the dependable operation and inherent risk mitigation of our power supply, our supplier qualification process is a multi-layered screening mechanism that leaves no room for compromise, ensuring only the most reliable and compliant partners are selected.

1. Multi-Dimensional Qualification Review

(1) Scrutinize suppliers’ business licenses, quality management system certifications (such as ISO 9001, ISO13485, IATF 16949), and product safety certificates(such as UL, CE, TUV cert).

(2) Conduct an in-depth evaluation of their customer base, cooperation history, industry reputation, and any records of significant quality issues or delivery delays.

(3) Pay particular attention to their safety records and any history of non-compliance within the industry to safeguard the exclusion of harmful substances at the source.

2. Professional On-Site Inspection

- We dispatch a team of R&D engineers, in collaboration with the quality department, to conduct a comprehensive on-site audit. This audit assesses the supplier’s production environment, equipment, and manufacturing processes. A key focus is the quality control procedures, including how they handle raw materials, in-process production, and final product inspection.

3. Legally Binding Quality Agreement

(1) After passing the qualification review and on-site evaluation, suppliers will be required to sign a formal Quality Agreement with UE Electronics. This agreement clearly stipulates product specifications, quality standards, responsibilities, and the consequences of non-compliance.

(2) We adopt a zero-tolerance policy towards unauthorized changes. Any modifications to material formulas, manufacturing processes, or subcontractors must be approved by us. We also reserve the right to inspect and test materials at the supplier’s site before shipment and require that key materials be fully traceable back to their original sources.

(3) Through this structured three-tier verification mechanism, we verify every partner meets our stringent quality and safety requirements.

Continuous Monitoring and System Audits

The supplier qualification is the first step of our supplier management system. We conduct continuous performance monitoring and systematic audits of all suppliers involved in manufacturing our power supply units. This confirms that they remain compliant over time.

(1) Regular System Audits

As part of our comprehensive supply chain risk management plan, we conduct periodic system audits according to a predefined schedule to verify suppliers’ quality management practices, production processes, and their consistent compliance with the standards specified in our quality agreements.

(2) Unannounced Surprise Audits

To maintain continuous vigilance, we also perform random, unannounced surprise audits. These audits aim to evaluate suppliers’ daily operational discipline, validating that their quality control practices are consistently adhered to. During these audits, our team may review production logs, inspect material storage conditions, and randomly select products for retesting.

Surprise audits provide a more accurate reflection of suppliers’ daily operations, preventing them from making temporary preparations solely for scheduled inspections. This approach reinforces UE Electronic’s steadfastness in transparency and accountability while effectively deterring suppliers from cutting corners on quality or safety.

Material Inspection and Multi-level Testing

Integral to our supplier management system, all incoming materials are subjected to a rigorous, multi-level testing protocol before they enter the production of our power supply units.

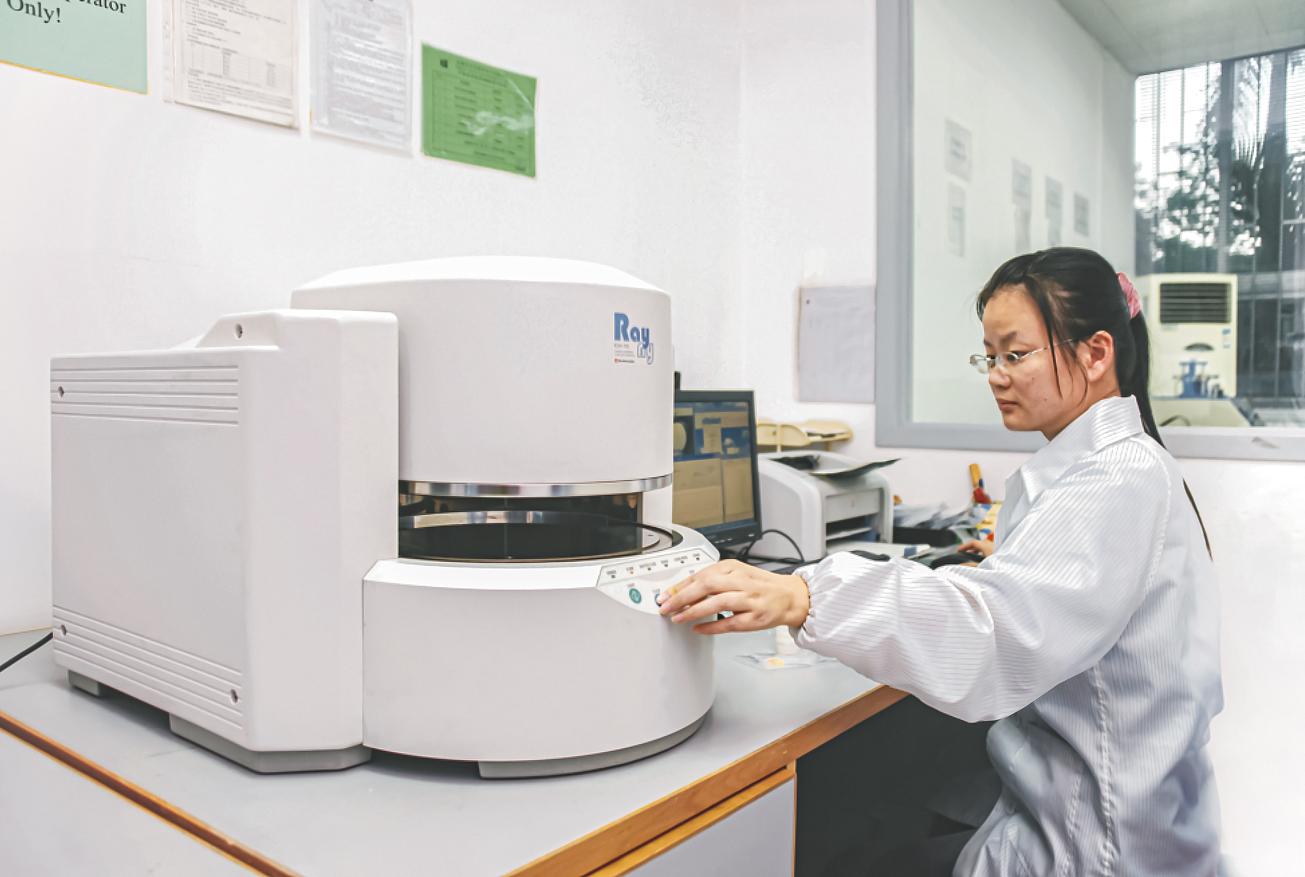

(1) IQC Sampling: All received components and raw materials undergo a strict Incoming Quality Control (IQC) sampling process. We meticulously check key electrical and performance parameters to affirm that every batch meets our specifications.

(2) ORT Testing Plan: We implement a comprehensive Ongoing Reliability Testing (ORT) plan, which involves putting materials through durability and performance tests over extended periods to simulate real-world usage and identify any potential long-term issues.

(3) Third-party Testing:For critical components, we employ reputable third-party laboratories to conduct independent, professional testing. This delivers an extra layer of validation and assurance, ensuring our materials meet or exceed international safety benchmarks.

Conclusion

At UE Electronic, our emphasis on safety is absolute. Our supplier management system is a testament to this commitment. From the initial qualification to continuous monitoring and multi-level material testing, every step is meticulously designed to ensure all our products meet or even exceed international safety standards. This rigorous supply chain audit in product design, raw material selection, and production processes guarantees the reliability and safety of our power supply solutions, instilling complete confidence in our customers.

Reference

[1]. Available at:

https://www.cpsc.gov/Recalls/2025/More-than-One-Million-Anker-Power-Banks-Recalled-Due-to-Fire-and-Burn-Hazards-Manufactured-by-Anker-Innovations